|

Process 2.5m*2.5m vertical lathe and 130 boring lathe

Mesh belt dryer

The dryer can be designed and produced by customers¨ requirements. Its length can reach 3-20m, layer 1-5 layers and temperature 200≧. It can be heated by oil, electricity, fuel and hot air. Its temperature can be controlled automatically and manually and its transmission speed can be regulated steplessly. The dyer is widely used to dry, dehydrate and solidify column, flake, bar and granule-like products in food, agricultural byproduct, dehydrated vegetable, Chinese medicinal material, aquatic product, special local product, feedstuff, and chemical material industries.

Featured by energy efficiency, the dryer has reached domestic leading level in cross-flow heating, layer ventilation, stepwise temperature adjustment and waste heat recovery.

The dyer uses multilevel movable stainless steel mesh belt or vibrating plate to stack materials processed. Hot air travels the mesh belt and its material layer from down to up. Its uniform and sufficient heat exchange boosts high production efficiency and quality products. Its cooling layer and rotating feeding device can reduce discharging temperature and are good for packaging. Its lifting device with a homogenizer ensures a uniform thickness which can be regulated steplessly. |

|

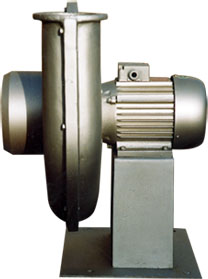

Spray

Cooling Fan

The characteristic of BW Spray Machine: vertical

variable-angle, bottom and top total 30 degress(respectively 15

degrees), horizontal 80 degress(respectively 40 degrees); the soft

link source depends on the rotating spray ring in the front of power

machine to spray.

BW Spray Machine is composed of spray device,

power machine(diagonal-flow fan) and spray ring(stainless steel),

with the central axis of spray device composed of three different

types of roller bearings. Applicable for where cooling or chilling

are needed in casting and textile industry etc, thanks to the excellent

capability, new structure and easy operation & installation.

Various height and overall dimensions are provided according to

customers. |

|

| |

|

☆Spray Cooling Fan Capability &

Preferred Parts List

NO. |

Rev r/min |

Matched Fanner |

| Type |

NO |

Flux

m/h |

Full

Pressure Pa |

Electromotor |

| Model |

Power KW |

| 1 |

900 |

XLT2 |

4 |

2911-1977 |

72.7-127.6 |

YS-7116 |

0.18 |

| 2 |

5 |

5587-3796 |

109-191 |

YS-8026 |

0.55 |

| 3 |

910 |

XLT2 |

6 |

8830-5954.5 |

138.5-273 |

Y90L-1 |

1.1 |

| 4 |

940 |

7 |

14315-9289.5 |

183.5-303 |

Y100L-6 |

1.5 |

| 5 |

960 |

8 |

24412-16583 |

317-555 |

Y132M2-6 |

5.5 |

| 6 |

970 |

XLT2 |

9 |

32438-22431 |

370-706 |

Y160M-6 |

7.5 |

| 7 |

10 |

40518-28649 |

367-963 |

Y160L-6 |

11 |

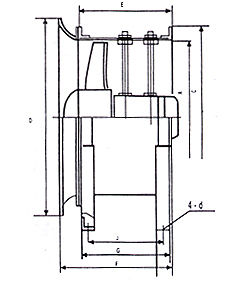

Centrifugal Fan

5-34、5-27NO1.2A 5-32NO1-6A Centrifugal Fans are the special low-noise

centrifugal fans designed basing on Japan NK5、NK200、NK500 centrifugal

fans according to the requirement of our national plactic industry.

This series of fans have some certain explosion-proof function owing

to the aluminium casting shell. Mainly used in manufacturers of

plastic films for blowing cooling, as well as factories and enterprises

for forced aeration; if the explosion-proof motor is provided, it

can be used as the explosion-proof fan. The environmental tempreture

is below 65≧ and the tempreture of conveying medium is below 80≧.

Gas and water vapour are forbidden in the conveying medium and the

dust quantity of which is less than 150mg/m3. The shell

of 5-35、5-27NO1.2A Fans can be made of cast iron and 5-32NO5.6A

can be made of stainless material(the shell,impeller and intake)

according to the requirement of customers. |

|

☆Centrifugal Fan Capability & Preferred

Parts List

| NO |

Transmission |

Rev r/min |

2900 Flux m/h1400 |

Full Pressure pa |

Noise dB(A) |

Electromotor |

| Model(B3) |

Power KW |

| 5-34 |

|

2800 |

719-246 |

392-1215 |

76 |

YS-7122 |

0.55 |

| 5-27 |

1 |

2840 |

1476-288 |

1294-2372 |

76 |

Y90S-2 |

1.50 |

| 2 |

1722-336 |

1433-2628 |

85 |

Y90L-2 |

2.20 |

| 5-32 |

1 |

2890 |

2882-504 |

1690-2710 |

90 |

Y112M-2 |

4.00 |

| 1400 |

1395-244 |

398-636 |

65 |

YS-8014 |

0.55 |

| 2 |

2890 |

2880-504 |

1695-2713 |

90 |

Y112M-2 |

4.00 |

| 140 |

1395-244 |

397-636 |

65 |

YS-8014 |

0.55 |

| 3 |

2870 |

2817-493 |

1670-2673 |

85 |

Y100L-2 |

3.00 |

| 1400 |

1400-245 |

411-658 |

62 |

YS-7124 |

0.37 |

| 4 |

2890 |

2185-1024 |

3754-4023 |

96 |

Y112M-2 |

4.00 |

| 1400 |

1058-496 |

879-958 |

66 |

YS-8014 |

0.55 |

| 5 |

2900 |

4440-1092 |

2692-3674 |

86 |

Y132S1-2 |

5.50 |

| 1400 |

2143-526 |

625-854 |

67 |

YS-8024 |

0.75 |

| 6 |

2900 |

5170-1740 |

3236-4123 |

88 |

Y132S1-2 |

7.50 |

| 1400 |

2492-526 |

252-958 |

69 |

Y-90L4 |

1.10 |

| 6-27 |

1 |

2900 |

621-72 |

6600-7492 |

76 |

Y90L-2 |

2.20

4.00 |

| 2 |

625-78 |

6630-7593 |

80 |

Y112M-2 |

| 7-10 |

|

2900 |

350-235 |

2942-3089 |

70 |

Y801-2 |

0.750 |

XLT2 Diagonal-Flow Fire-Protection

Fan

Compared with centrifugal fans and axial-flow fans

of the same number and power, the flux of XLT2 Diagonal-Flow Fan

is higher than the former and the full pressure is higher than the

latter. The figure dimension

is relatively small and the weight is between the centrifugal and

axial-flow ones. Owing to the sound structure, this type of fans

has relatively low noise, high efficiency and smooth operation when

running. It is the new product to replace axial-flow and mixed-flow

fans. The figure dimension

is relatively small and the weight is between the centrifugal and

axial-flow ones. Owing to the sound structure, this type of fans

has relatively low noise, high efficiency and smooth operation when

running. It is the new product to replace axial-flow and mixed-flow

fans.

Thanks to the topping quality, new structure and

easy installation, it is widely used in factories, mines, hotels

and underground facilities of tall buildings as well as the distant

series installation in relatively long vent pipes so as to increase

the full pressure in the pipe. The noise index is generally 65-80dB(A),

better than the national standard 85dB(A) and up to the international

standard 80dB(A). It can be made of stainless materials and changed

into ingle-phase electromotor according to the customers. This type

of fans is used to transport non-corrosive gas with dust granule

less than 160mg/m3 and temperature between 25≧ to 65≧. |

☆XLT2 Diagonal-Flow

Fire-Protection Fan Capability & Preferred Parts List

No |

Transmission |

Rev r/min |

Flux m/h |

Full Pressure

pa |

Electromotor |

Noise dB(A) |

Weight kg |

| Model |

Power KW |

Installation |

| 4 |

A |

1400 |

4529-3076 |

176-390 |

YS-8014 |

0.55 |

B14 |

76 |

52 |

| 900 |

2911-1977 |

72.7-127.6 |

YS-7116 |

0.18 |

65 |

| 4.5 |

A |

1400 |

6392-4344 |

224-391 |

YS-8024 |

0.75 |

B14 |

77 |

61 |

| 900 |

4109-2792.5 |

92.5-161.5 |

YS-7126 |

0.25 |

66 |

| 5.0 |

A |

1430 |

8877-6032 |

276-482 |

YS-90L4 |

1.50 |

B14 |

80 |

82 |

| 900 |

5587-3796 |

109-191 |

YS-8026 |

0.55 |

68 |

| 5.5 |

A |

1430 |

11815-8026 |

334-583 |

Y100L1-4 |

2.320 |

B5 |

80 |

102 |

| 900 |

7436-5051 |

132-231 |

YS-90L6 |

0.75 |

B14 |

68 |

| 6.0 |

A |

1430 |

13876-9357 |

342-674 |

YS100L2-4 |

3.00 |

B5 |

84 |

115 |

| 910 |

8830-5954.5 |

138.5-273 |

Y90L-6 |

1.10 |

70 |

| 6.5 |

A |

1430 |

16763-10876 |

366-665 |

Y100L2-4 |

3.00 |

B5 |

81 |

121 |

| 940 |

11019-7149 |

158-261 |

Y90L-6 |

1.10 |

69 |

| 7.0 |

A |

1440 |

21930-14231 |

431-712 |

Y112M-4 |

4.00 |

B5 |

83 |

141 |

| 940 |

14315-9289.5 |

183.5-303 |

Y100L-6 |

1.50 |

69 |

| 8.0 |

A |

960 |

24412-16583 |

317-555 |

Y132M2-6 |

5.50 |

B5 |

83 |

219 |

| 9.0 |

970 |

32438-22431 |

370-706 |

Y160M-6 |

7.50 |

86 |

358 |

| 10.0 |

A |

970 |

40518-28649 |

369-763 |

Y160L-6 |

11.00 |

B5 |

86 |

438 |

| 11.0 |

970 |

53971-38165 |

446-721 |

Y180L-6 |

15.00 |

87 |

552 |

| 12.0 |

A |

970 |

66365-29685 |

450-845 |

Y180L-6 |

15.00 |

B5 |

90 |

596 |

GDFC Dry Low-Noise Dust Trap

| |

|

GDFC Dry Low-Noise Dust Trap is

a cabinet dust removing plant

with homemade 5-34、5-27、5-32 fans as the host machine which

are designed basing on Japan NK5、N200、NK500, according to the

requirements of our electric, electric appliance and small woodwork

industry. The features include good dust-removing effect, low

noise, nice appearance, small space  and

easy installation & operation. It is mainly used as the

dust-removing device for PVC components of TV, computer, mobile

phones, telephones and electric facilities, as well as used

in the wood materials process such as chopsticks and toothpicks

etc. Environmental temperature is less than 65≧ and medium temperature

is less than 80≧ without corrosive materials in it and the dust

granule less than 150mg/m3. and

easy installation & operation. It is mainly used as the

dust-removing device for PVC components of TV, computer, mobile

phones, telephones and electric facilities, as well as used

in the wood materials process such as chopsticks and toothpicks

etc. Environmental temperature is less than 65≧ and medium temperature

is less than 80≧ without corrosive materials in it and the dust

granule less than 150mg/m3.

|

|

| |

|

☆GDFC Dry Low-Noise

Dust Trap Capability & Preferred Parts List

NO. |

Shape |

Noise dB(A) |

Rev r/min |

Match Fan |

| Type |

Flux m/h |

Full Pressure

Pa |

Electromotor |

| Model |

Power KW |

| 1 |

Small |

63 |

2800 |

5-34 |

719-246 |

392-1215 |

YS-7122 |

0.55 |

| 2 |

Medium |

65 |

2800 |

5-27-1 |

1476-288 |

1294-2372 |

Y90S-2 |

1.50 |

| 5-27-2 |

1722-336 |

1433-2628 |

Y90L-2 |

2.20 |

| 3 |

Large |

72 |

2890 |

2-32-1 |

2882-504 |

1690-2710 |

Y112M-2 |

4.00 |

| 63 |

1400 |

1395-244 |

397-636 |

YS-8014 |

0.55 |

| 74 |

2890 |

5-32-1 |

2880-504 |

1695-2713 |

Y112M-2 |

4.00 |

| 64 |

1400 |

1395-244 |

397-636 |

YS-8014 |

0.55 |

| 76 |

2870 |

5-32-3 |

2817-433 |

1670-2673 |

Y100L-2 |

3.00 |

| 64 |

1400 |

1400-245 |

411-658 |

YS-7124 |

0.37 |

| 77 |

2890 |

5-32-4 |

2185-1024 |

3754-4203 |

Y112M-2 |

4.00 |

| 65 |

1400 |

1058-496 |

879-958 |

YS-8014 |

0.55 |

| 4 |

Super |

77 |

2900 |

5-32-5 |

4440-1092 |

2692-3674 |

Y132S1-2 |

5.50 |

| 65 |

1400 |

2143-526 |

625-854 |

YS-8024 |

0.75 |

| 77 |

2900 |

5-32-6 |

5170-1740 |

3236-4123 |

Y132S2-2 |

7.50 |

| 65 |

1400 |

2492-526 |

752-958 |

YS-90L4 |

1.10 |

DF Low-Noise Centrifugal

Fan

The characteristic of FNO1 、 2 、 3 、 6 、 7 、 12 Low-Noise Centrifugal

Fan is that the impeller is forward multi-winged petiole type. Its

capability index is one-up compared with products of the same kind,

owing to the sound structure, large flux, high pressure coefficient,

stable performance, realible operation, easy maintenance and low

noise. Used for aeration and cooling of plastic machinery, film-print

machine, copycats, blueprint machine, food processing machinery,

air-conditioners and various facilities, especially suitable for

those where little vibration and low noise are needed. The conveying

medium is air and non-corrosive gas without viscous things and the

dust granule in it is less than 50mg/m3, temperature lower than

55 ≧. 220V out-of-phase electromotor can also be provided according

to the customer. Meanwhile, the shell of DFNO7A is made of aluminum

casting alloy so it has some certain explosion-proof function.

☆DFNO1-12A

Low-Noise Centrifugal Fan Figure & Installation Size List

|

NO |

Transmission |

Rerv

r/min |

Flux

m3/h |

Full

Pressure Pa |

Noise

dB(A) |

Electromotor |

(B3) |

KW |

1 |

A |

2800 |

545-390 |

889.8-469 |

75 |

YS-7112(B14) |

0.37 |

2 |

2800 |

840 |

1270 |

78 |

YS-7122(B14) |

0.55 |

3 |

2800 |

198 |

294 |

58 |

A02-5012(B14) |

0.04 |

6 |

2800 |

1080 |

1666 |

82 |

YZA-7132(B14) |

0.75 |

7 |

2800 |

1290 |

784 |

66 |

YS-7122(B14) |

0.55 |

12 |

2800 |

918 |

950 |

78 |

YS-7112 |

0.37 |

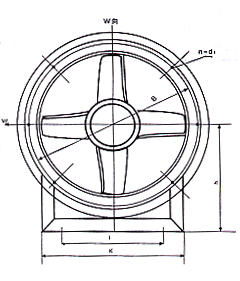

Dimension & Installation Size List of T35, BT35, BFT35 axial-flow blowers

Article #NO. |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

n |

d1 |

d2 |

Weight |

| 2.8 |

283 |

320 |

346 |

355 |

220 |

258 |

212 |

220 |

100 |

175 |

260 |

4 |

10 |

12 |

10.26 |

| 3.15 |

316 |

355 |

381 |

400 |

240 |

282 |

232 |

240 |

220 |

190 |

300 |

8 |

10 |

12 |

13.2 |

| 3.55 |

358 |

385 |

422 |

450 |

280 |

327 |

272 |

260 |

240 |

230 |

330 |

8 |

10 |

12 |

14.28 |

| 4 |

404 |

450 |

478 |

500 |

300 |

349 |

292 |

290 |

280 |

240 |

370 |

8 |

12 |

12 |

21 |

| 4.5 |

454 |

500 |

528 |

580 |

260 |

314 |

252 |

330 |

310 |

205 |

430 |

8 |

12 |

12 |

22.9 |

| 5 |

504 |

560 |

588 |

630 |

300 |

364 |

290 |

340 |

410 |

240 |

430 |

12 |

12 |

12 |

30.9 |

| 5.6 |

564 |

620 |

649 |

710 |

330 |

404 |

318 |

390 |

440 |

260 |

490 |

12 |

12 |

14 |

41.3 |

| 6.3 |

634 |

690 |

719 |

800 |

390 |

474 |

378 |

440 |

490 |

320 |

540 |

12 |

12 |

14 |

57.5 |

| 7.1 |

715 |

720 |

800 |

900 |

400 |

494 |

388 |

490 |

630 |

330 |

700 |

16 |

12 |

14 |

87.8 |

| 8 |

805 |

860 |

891 |

1000 |

480 |

579 |

468 |

550 |

700 |

380 |

770 |

16 |

12 |

18 |

90.8 |

| 9 |

905 |

970 |

1001 |

1120 |

540 |

648 |

526 |

610 |

810 |

440 |

850 |

16 |

15 |

18 |

121 |

| 10 |

1006 |

1070 |

1103 |

1250 |

630 |

753 |

616 |

670 |

890 |

505 |

956 |

16 |

15 |

22 |

151 |

| 11.2 |

1126 |

1190 |

1223 |

1400 |

700 |

888 |

686 |

760 |

1080 |

580 |

1289 |

20 |

15 |

22 |

192 |

|